FlexRay is a high-speed, deterministic, and fault-tolerant communication protocol used in modern vehicles, particularly prominent in BMW models. This article delves into the intricacies of FlexRay, its history with BMW, configuration, and implications for diagnostics and repairs.

FlexRay Protocol Overview

FlexRay boasts significantly faster data transfer rates than traditional CAN bus systems, ranging from 500 Kbps to 10 Mbps. This speed, coupled with its time-triggered communication, makes it ideal for safety-critical systems requiring real-time data exchange. Applications include engine control, braking systems, steering, and more. Unlike event-triggered protocols, FlexRay operates on a precise schedule, ensuring predictable message delivery.

FlexRay supports various network topologies, including:

- Multi-drop Bus: Similar to CAN and LIN systems, this topology utilizes a single twisted-pair wire to connect multiple modules. Its compatibility with existing layouts simplifies integration.

- Star Network: ECUs connect to a central active node, enhancing fault tolerance. If one module fails, the rest of the network remains operational.

- Hybrid Network: Combining aspects of both multi-drop and star topologies, this configuration offers flexibility and redundancy.

FlexRay and BMW: A History

BMW was instrumental in the development of FlexRay through its participation in the FlexRay Consortium. The 2008 BMW X5 (E70) marked the first production vehicle to incorporate a FlexRay network for its Vertical Dynamics Control Module, managing suspension height adjustments. Subsequent generations, including the F and G series, expanded FlexRay integration to encompass critical modules like the Engine Control Module (ECM), also known as DME or DDE.

FlexRay Configuration in BMW

BMW typically employs a star bus configuration for its FlexRay networks. This setup ensures continued operation even with module failures and mitigates the impact of electrical interference, particularly beneficial with long wiring harnesses. Modules are often strategically placed at the vehicle’s corners.

Diagnostics and the FlexRay Network

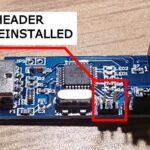

When diagnosing or programming BMW modules with integrated FlexRay, specific procedures are required. Tools like Autohex and Hexprog necessitate connecting the FlexRay twisted wires from the target module (e.g., DME/DDE) to the gateway module (FEM, BDC, or ZGW). Additionally, the CAN bus connection between the module and gateway must also be established. Without these connections, OBD communication with the module is often impossible.

Conclusion

FlexRay plays a vital role in modern BMW vehicles, enabling high-speed, reliable communication for critical systems. Understanding its architecture, configuration, and diagnostic requirements is crucial for technicians and enthusiasts alike. As vehicle technology continues to advance, FlexRay’s importance will only continue to grow. For more detailed technical information or troubleshooting assistance, consulting specialized resources or contacting technical support teams is recommended.