A fuel pressure regulator is a vital component in any fuel injection system, responsible for maintaining the correct fuel pressure for optimal engine performance. Understanding how a fuel pressure regulator works is crucial for diagnosing and resolving fuel-related issues. This guide will delve into the mechanics of fuel pressure regulators, exploring different types and their applications.

Understanding Fuel Pressure and Injectors

Before diving into the regulator itself, it’s important to understand why precise fuel pressure is necessary. Fuel injectors deliver fuel into the engine cylinders at a specific rate. This rate is determined by the fuel pressure and the injector’s design. At idle, most engines create a vacuum in the intake manifold. This vacuum affects the pressure difference (pressure delta) across the injector.

For example, if your fuel pressure is 42 psi and the engine vacuum is 8 psi, the effective pressure at the injector is 50 psi (42 + 8). As engine load increases, manifold pressure also rises, potentially decreasing the pressure delta across the injector.

Maintaining Pressure Delta: The Role of the Regulator

Ideally, the pressure delta should remain constant across various engine loads. This is where the fuel pressure regulator comes in. A common approach is to use a rising-rate fuel pressure, maintaining a 1:1 ratio between manifold pressure and fuel pressure changes.

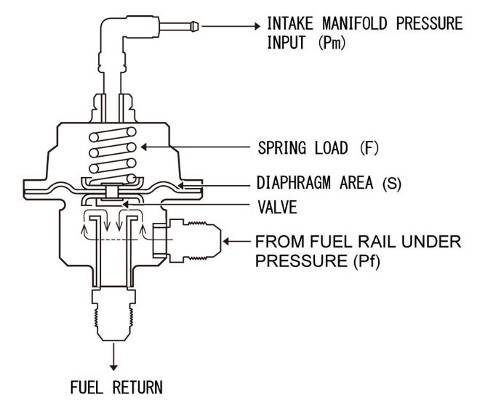

Figure 1. A typical aftermarket manifold referenced fuel pressure regulator.

Manifold Referenced Fuel Pressure Regulators

These regulators use a vacuum hose connected to the intake manifold. The vacuum/pressure acting on a diaphragm within the regulator, along with a mechanical spring, adjusts the fuel pressure in proportion to manifold pressure changes. This 1:1 ratio ensures a constant pressure delta across the injector.

How a Manifold Referenced Regulator Works:

- Fuel Entry: High-pressure fuel enters the regulator and flows into a sealed chamber.

- Diaphragm and Spring: The fuel pressure pushes against a diaphragm, which acts against a spring.

- Vacuum Influence: Manifold vacuum also acts on the diaphragm. Increased engine demand (and manifold pressure) increases the force on the diaphragm.

- Bypass Regulation: At low demand, excess fuel bypasses back to the fuel tank through a return line.

- Increased Demand: As engine demand increases, less fuel bypasses, ensuring sufficient fuel delivery to the injectors.

- Fuel Pump Capacity: If the fuel pressure no longer increases proportionally to manifold pressure, the fuel pump has reached its capacity.

Figure 2. The C5 Corvette Fuel Filter Regulator (FFR). This design combines fuel filtering and pressure regulation in a single unit. Note the inlet and return on the left, and the regulated outlet on the right.

Non-Manifold Referenced Regulators

These regulators don’t use a vacuum reference and maintain a relatively constant fuel pressure. They are common in naturally aspirated engines where the engine calibration compensates for the changing pressure delta. A popular example is the C5 Corvette’s Fuel Filter Regulator (FFR), which combines filtering and regulation. These regulators typically exhibit a slight pressure drop at high fuel flow rates.

Forced Induction and Large Injectors

In forced induction applications, a 1:1 manifold referenced regulator is often preferred to maintain sufficient fuel delivery under boost. Large injectors in high-fuel-pressure systems can benefit from manifold referencing, allowing for lower idle pressures and improved idle quality. This prevents injectors from operating at excessively low duty cycles, ensuring proper functionality.

Safety Overpressure Regulation

Modern returnless fuel systems often incorporate a safety overpressure regulator to prevent dangerously high fuel pressures. These regulators protect the fuel system components from damage due to heat soak or other factors that can cause pressure spikes. They typically relieve pressure above 75-90 psi. For aftermarket high-flow fuel pumps in returnless systems, an external overpressure regulator is recommended.

Figure 3. Diagram showcasing a safety overpressure regulator setup for a dual or triple pump system with an external bypass.

Conclusion

The fuel pressure regulator plays a critical role in ensuring proper engine performance and fuel delivery. Understanding the different types of regulators and their operating principles is essential for anyone working on fuel injection systems. By maintaining the correct fuel pressure, the regulator allows for optimal fuel atomization, efficient combustion, and overall engine reliability.